Major events like pandemics, tariffs, and trade wars can all massively disrupt supply chains. Even when the economic landscape is calm, supply chain operations require a degree of flexibility; changes in demand, resource discovery and depletion, and the weather can all affect the flow of goods around the world.

Businesses regularly assess, track, and measure the effectiveness of their supply chain strategy using the SCOR DS model, which stands for Supply Chain Operations Reference Digital Standard. This tool is useful for assessing, managing, and improving supply chains by making the most informed supply chain management decisions possible.

What is the SCOR DS model?

The Supply Chain Operations Reference Digital Standard, or SCOR DS model, is a comprehensive, open-source supply chain analysis system first created in 1996 and updated periodically by the Association for Supply Chain Management (ASCM) to account for technological advancements. “The SCOR DS model was created based on the insights of 70 subject-matter experts from around the globe, and the processes are designed to apply to nearly any product or service,” says Mindy Weinstein, the ASCM’s Director of Communications. By providing benchmarks and best practices, the SCOR DS model helps companies and organizations manage their supply chains.

The SCOR DS model has four sections:

- Processes. The SCOR process section includes standardized descriptions of the processes a supply chain requires to fulfull customer orders.

- Performance. The performance section offers an approach to measuring and assessing how well your supply chain works.

- People. The people section provides standardized definitions of skills needed to manage the talent involved in supply chain activities.

- Practices. The practices section bridges the other three sections by providing tested, repeatable tips that can improve supply chain performance and help you meet business goals.

The SCOR DS model is often applied to businesses with particularly complex supply chains, such as big box retailers with tens of thousands of suppliers. However, the model is malleable and can be used to assess the supply chain efficiency of a small business. While straightforward linear supply chains exist, most are dynamic with multiple moving parts, so a systematized set of best practices and standards can help achieve efficiency.

7 SCOR DS processes

- Plan

- Order

- Source

- Transform

- Fulfill

- Return

- Orchestrate

There are seven SCOR Digital Standard process elements that provide a framework for optimizing supply chain performance. Although these primary processes apply to most supply chains, they are often modified to fit the specific needs of individual businesses.

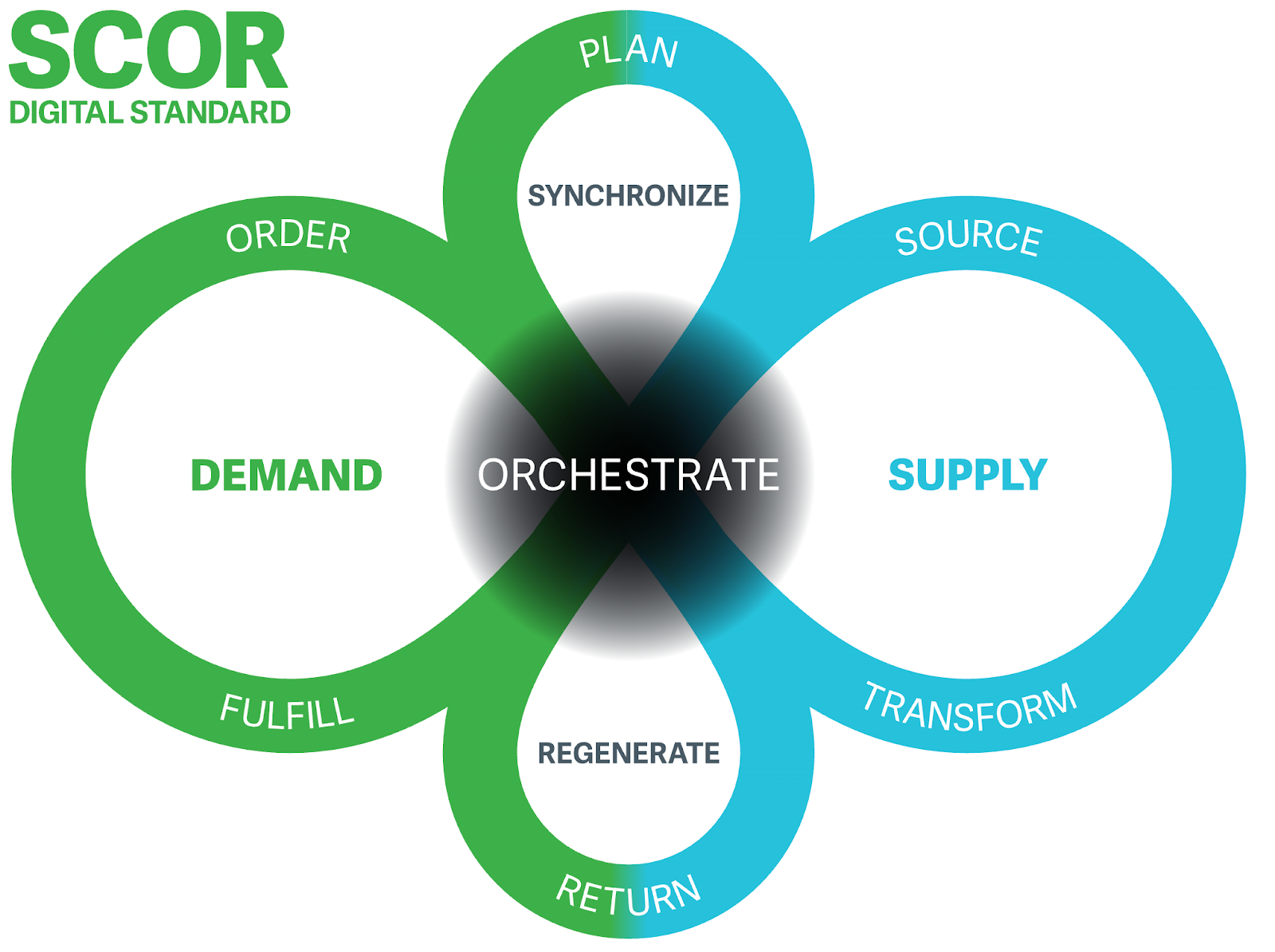

For a top-level conceptual view, the model is represented as two overlapping infinity loops: supply feeding into demand and back again, with synchronization and regeneration processes cycles playing out in tandem. Six supply chain processes (plan, source, transform, order, fulfill, return) sit within these loops, all underpinned by the orchestration process.

Mindy underscores that the seven SCOR processes are not part of a linear timeline. “Everything happens at once and sometimes in different orders or by looping back to repeat processes. The model is interconnected, dynamic, and synchronous, just like today’s supply chains.”

To illustrate how this model works, Mindy uses yoga pants as an example in each SCOR DS stage:

1. Plan

In the planning stage, you assess supply and demand for a particular piece or product. “For example,” Mindy says, “if demand [for yoga pants] typically spikes in January as people kick off their New Year’s resolutions, we plan for that demand by making sure procurement knows how much material to purchase, production knows how much to make, and transportation is prepared to deliver the level of output.”

She adds that planning also includes preparing supply chain issues such as natural disasters that may hinder production or delivery, or even a spike in demand due to an influencer’s social media post. Using supply chain forecasting can help you mitigate issues as they arise.

2. Order

The ordering process focuses on the demand side of the supply chain in more detail: when and where customers, whether individuals or businesses, purchase goods. Returning to the yoga pants example, Mindy says that the order stage involves “how many pairs are ordered in what sizes and colors, how the customer will pay for the yoga pants, when the pants need to be delivered, and any other order details.” This phase overlaps with the planning phase and includes supply planning and order management—the process of tracking orders, inventory, and fulfillment.

3. Source

This SCOR DS process covers the key aspects of strategic procurement from supply chain partners. On the tactical side of a product like yoga pants, Mindy notes that this involves the ordering of materials, tags, stickers, and packaging. Sourcing also includes “receiving those material orders and transferring the materials to the production steps,” she says.

This stage includes racking raw materials, managing supplier agreements, and overseeing quality control. “From a strategic standpoint,” Mindy adds, “focus on ensuring the material is ethically sourced, the material is of the appropriate quality, and the supply is steady and affordable. You also need an action plan for supply disruptions.”

4. Transform

The transformation stage includes the manufacturing process and describes how the final product is made. It includes production activities, such as manufacturing a finished product or assembling a product with custom-engineered, standard-stock, or made-to-order pieces. It also covers storing, staging, and packing—all activities that need to be completed in preparation to ship products. For this process, Mindy emphasizes that “from an ethical standpoint, it’s important to ensure your producers are treated well and paid fairly.”

5. Fulfill

This stage of SCOR DS includes the distribution and delivery of finished products on time and in full via freight, air, trucking, or other means. It covers the full order fulfillment process, including import and export requirements and interim warehousing, if necessary. When it comes to determining your most effective routes for fulfillment, Mindy says that efficiency applies to both time and environmental impact.

6. Return

Return processes involve any products that are returned, whether by customers or to suppliers. Products or parts may be defective when you receive them from a supplier, or you might have received an incorrect order. On the customer side, those yoga pants may not work for their needs or be the right fit. Returns management facilitates the flow of returns between customers and a business.

This stage includes customer interactions and support for returned items. Depending on the situation and the product, you may be able to resell returned products (either at full price or with a discount), or you may need to dispose of them in an environmentally responsible manner that meets sustainability standards.

7. Orchestrate

Orchestration overlaps with the other six supply chain processes and ensures operational support. “Supply chain is not just a function of a company,” Mindy says. “It’s an integral lifeblood of a business. It is connected to and supported by the other major organs of a company. Human resources finds and supports the talent that makes supply chain processes possible, IT supports the technical systems that enable operations, accounting pays the bills, and so on.” Your legal team might ensure regulatory compliance, while your risk management team helps you navigate around threats to your business—all in support of a perfectly synchronized supply chain.

Essential SCOR DS performance metrics

There are more than 250 SCOR DS metrics to analyze, divided into three levels. The metrics your business prioritizes will be contingent on your operations and needs, but in general, they should help you achieve agility, asset management efficiency, costs, reliability, and responsiveness.

Level 1

Level 1 metrics are key performance indicators (KPIs) that measure the health of a supply chain compared to industry standards. ASCM corporate members can see how their performance measurement on a given metric compares with others in their industry.

Using Mindy’s yoga pants example, you might compare the percentage of yoga pants orders with on time delivery, in full, without damage, and in the right size and color—known as “perfect customer order fulfillment”—with competitors’ average numbers to see how you stack up.

Level 2

This level of SCOR DS performance metrics goes into more complex detail, assessing subcategories of various Level 1 metrics. For example, “perfect customer order fulfillment” has four Level 2 metrics, one of which is “customer order perfect condition.” Level 2 metrics help identify the causes of performance gaps in your Level 1 metrics, identifying the areas where you might be falling behind.

Level 3

This level spotlights any performance gaps in Level 2 metrics. According to Mindy, an example of a Level 3 metric is “percentage of customer orders or lines received damage free,” which she notes ties back to activities like inspecting products upon delivery and obtaining customer confirmation that the items were received in acceptable condition.

“When a metric shows that a process is not performing well,” Mindy adds, “the SCOR user would next turn to best practices for ideas about how to improve the process. These would then help form an improvement plan to improve the KPI.”

Pros and cons of SCOR DS

Using SCOR DS to evaluate, manage, and make operational improvements to your supply chains comes with pros and cons:

Pros

- It’s a universally used system with shared vocabulary and process knowledge, making it easy to use with other businesses in multiple environments.

- It offers the ability to compare your business’s performance metrics to industry standards.

- It can save you money. Mindy reports that the typical results for SCOR DS users include two to six times return on investment in the first year, 30% faster digital transformation project implementation, and reduced IT operating expenses.

Cons

- There is a steep learning curve when first using the SCOR DS model, which could be time-consuming and potentially costly—SCOR training courses, for instance, can cost more than $1,000.

- You’ll need access to reliable internal data resources for accurate metric comparisons, and setting up a system to gather supply chain analytics is an extensive endeavor in itself.

- The complexity of the model can be overwhelming for smaller enterprises, and adapting the model to niche industries may require hiring a consultant.

SCOR model supply chain FAQ

What is the SCOR DS model of supply chain management?

The SCOR framework is a collection of reference materials that help businesses manage and improve their supply chains. The SCOR DS model is primarily used for managing complex supply chains.

What are the seven SCOR DS model processes?

The seven major processes are plan, order, source, transform, fulfill, return, and orchestrate. Breaking down a dynamic supply chain into smaller pieces makes analysis, performance management, and continuous improvement easier to accomplish.

What is SCOR DS supply chain reliability?

Reliability is a SCOR DS performance attribute and refers to the ability to perform tasks as expected. Typical reliability metrics include on time, the right quantity, and the right quality.